Project Objective:

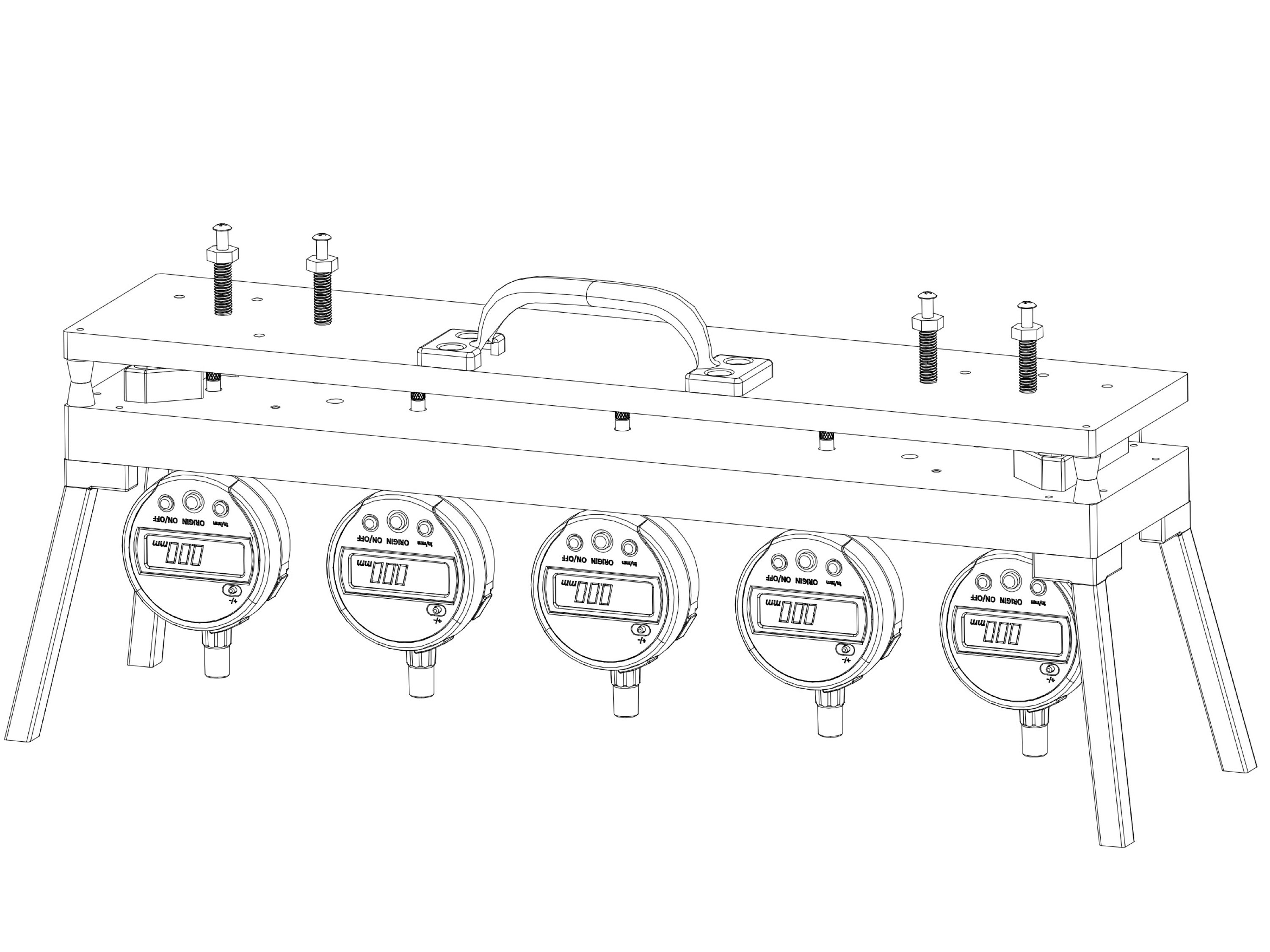

By analyzing the effect of weave density, weave type, and matrix density on carbon fiber mechanical properties under uniaxial tension testing, we strove to determine a relationship between composite makeup and mechanical behavior. Analysis was completed using SEM imaging and through uniaxial Instron testing.

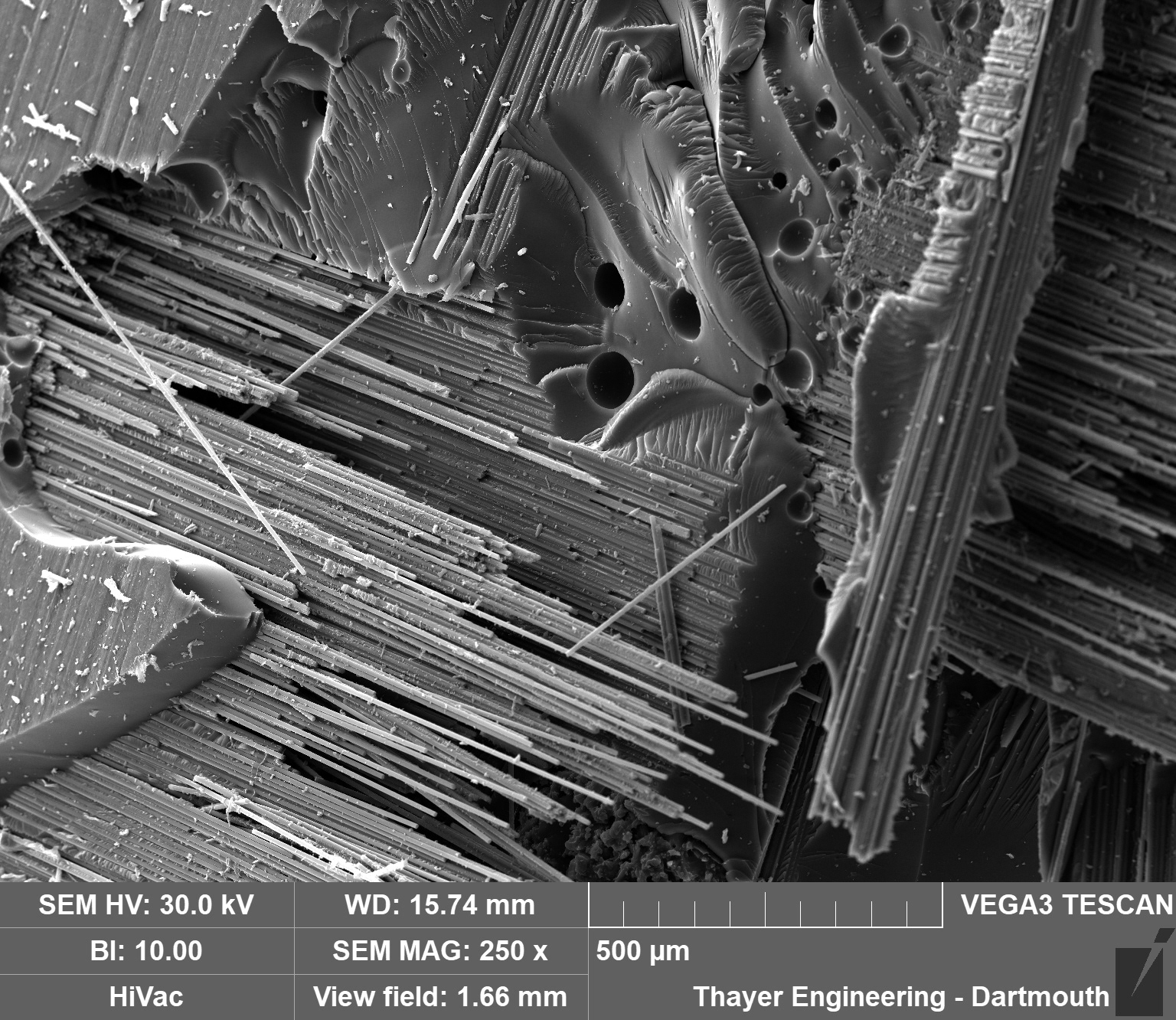

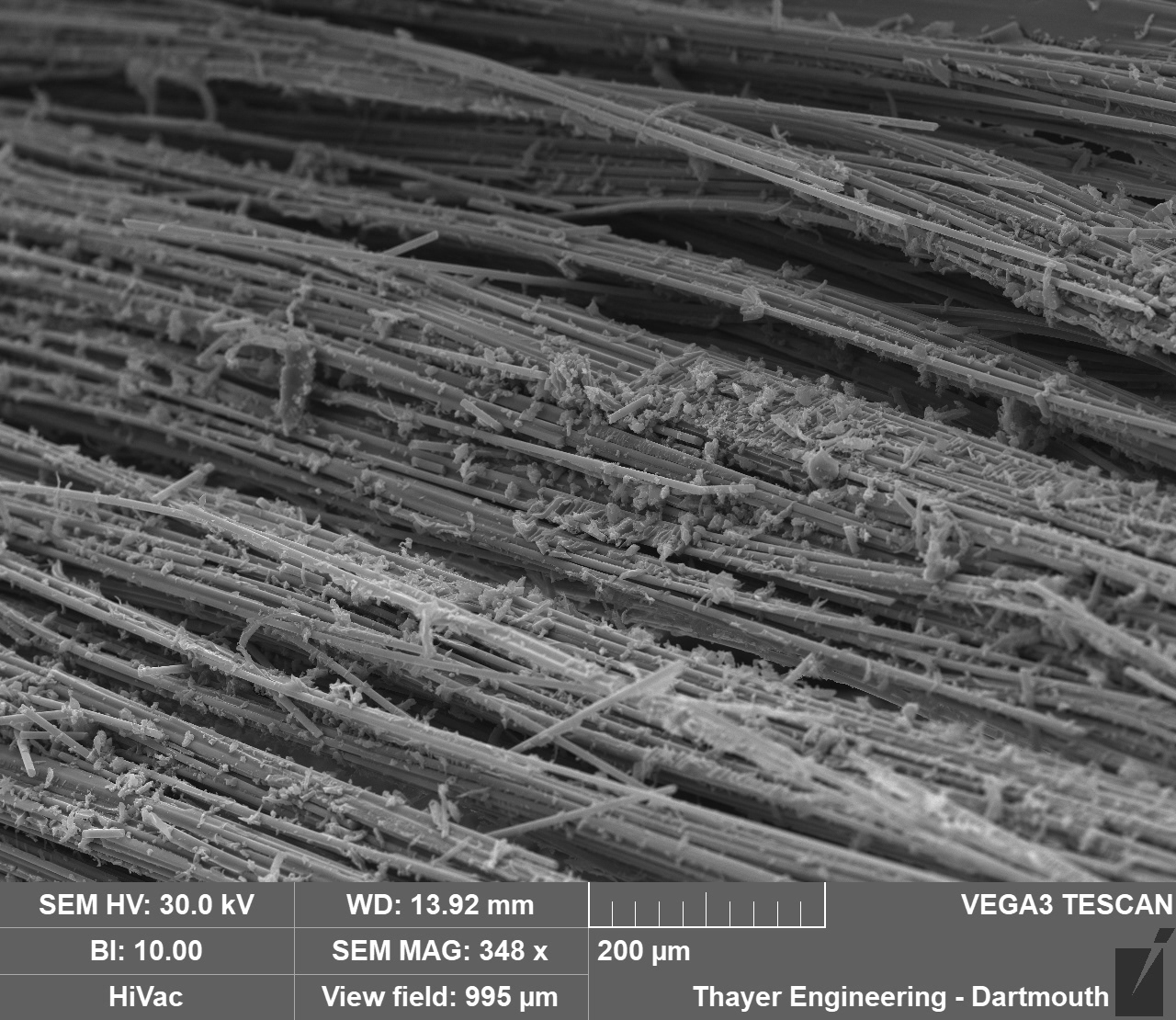

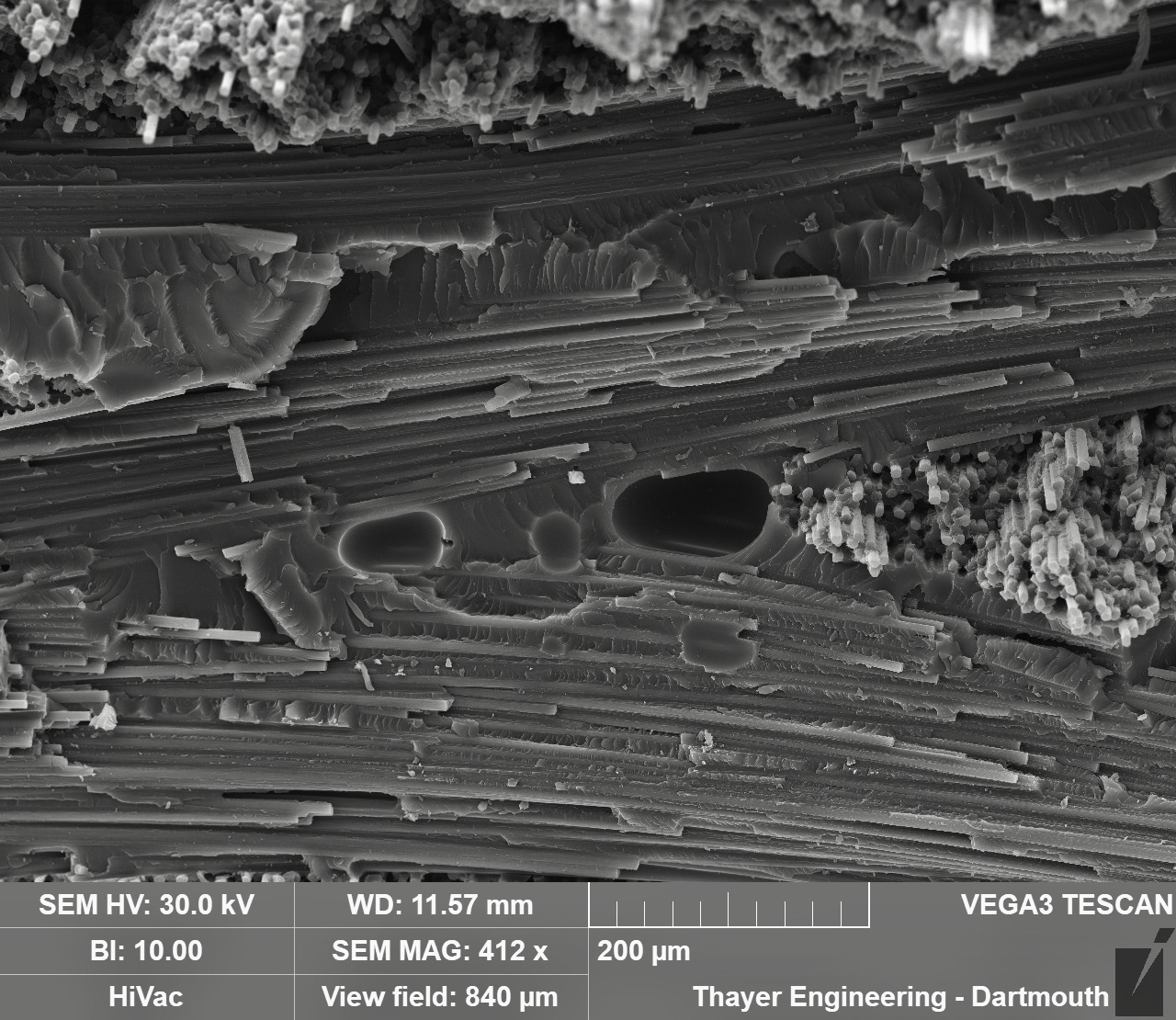

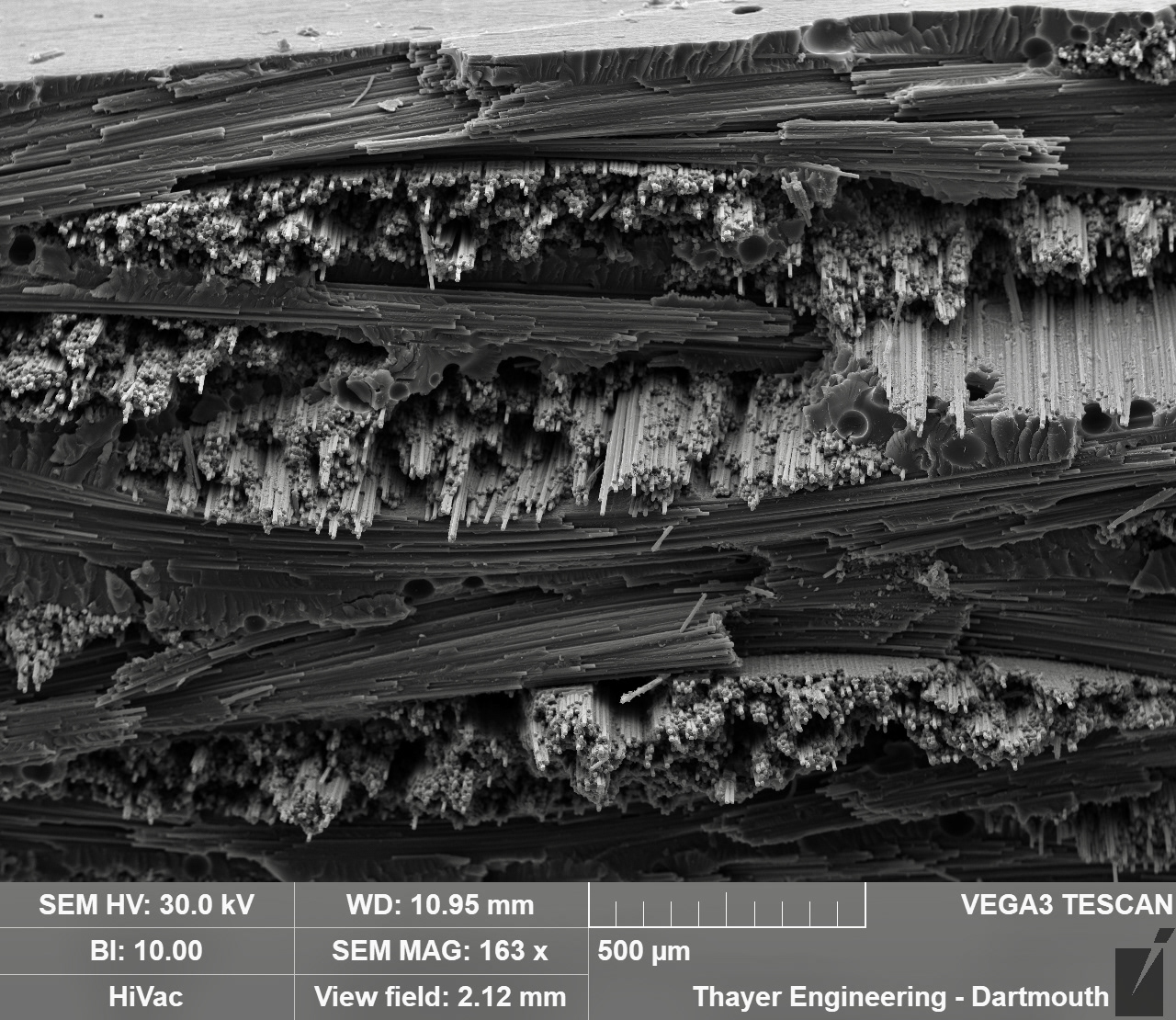

Stress Concentrations in Matrix

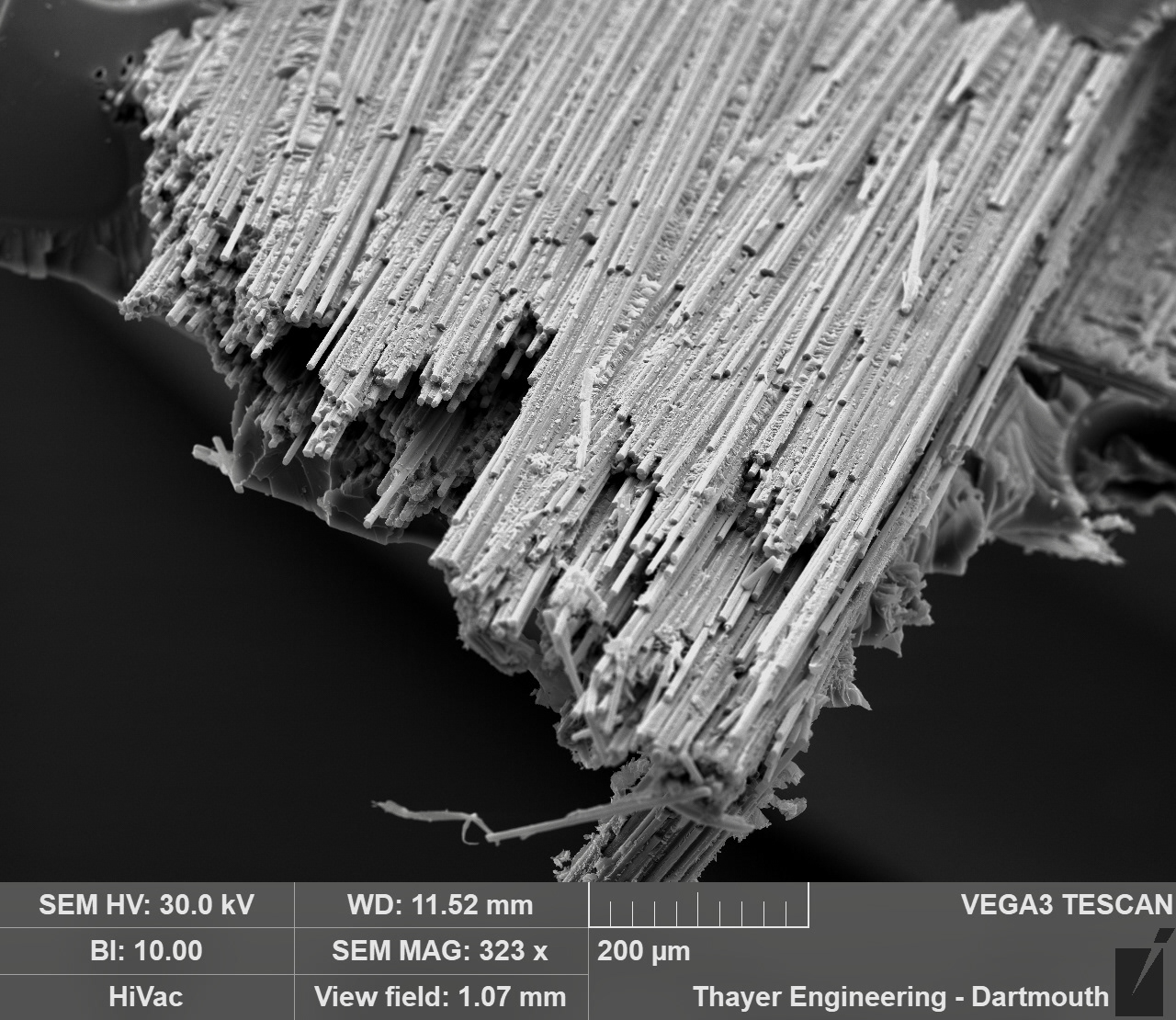

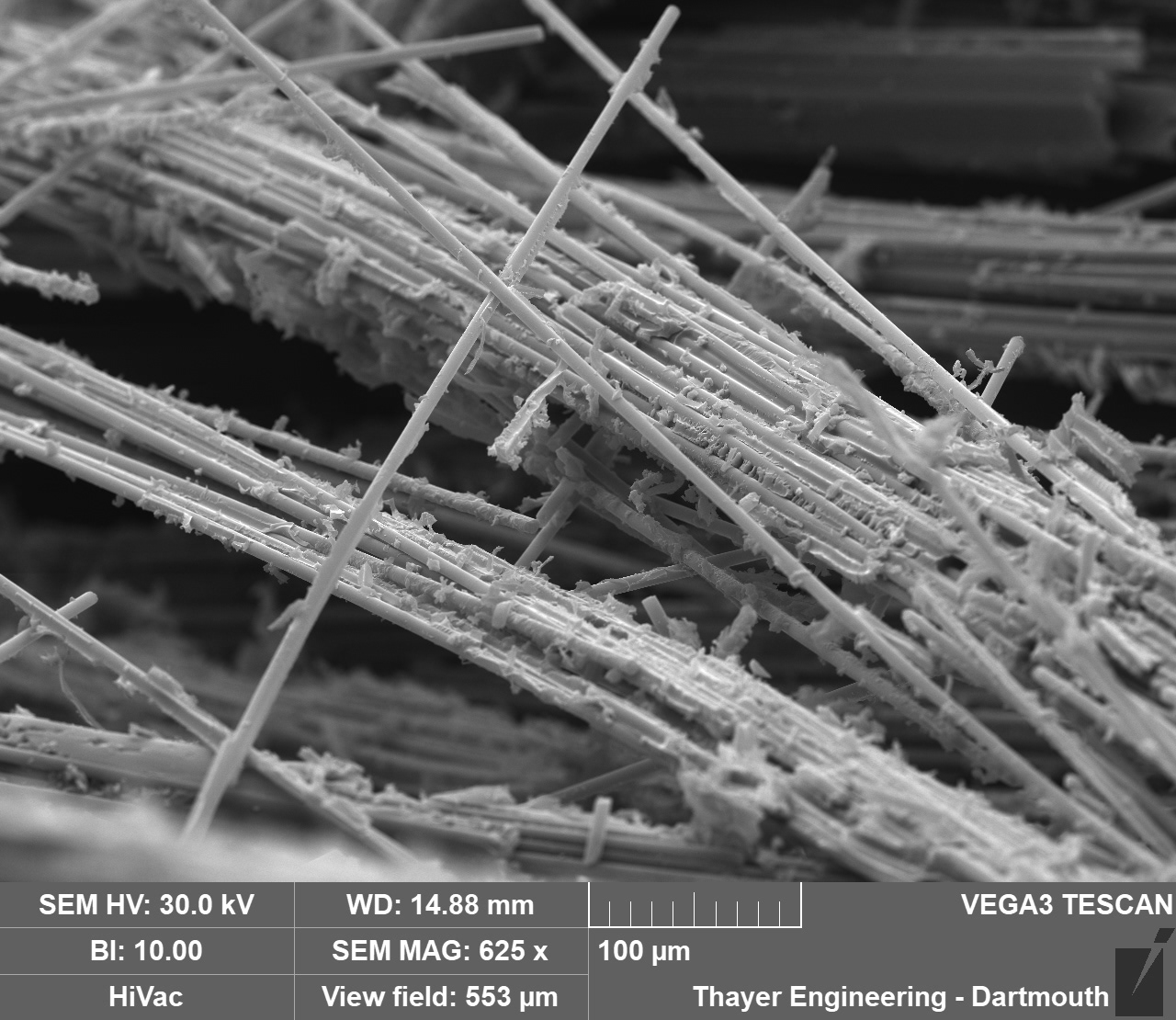

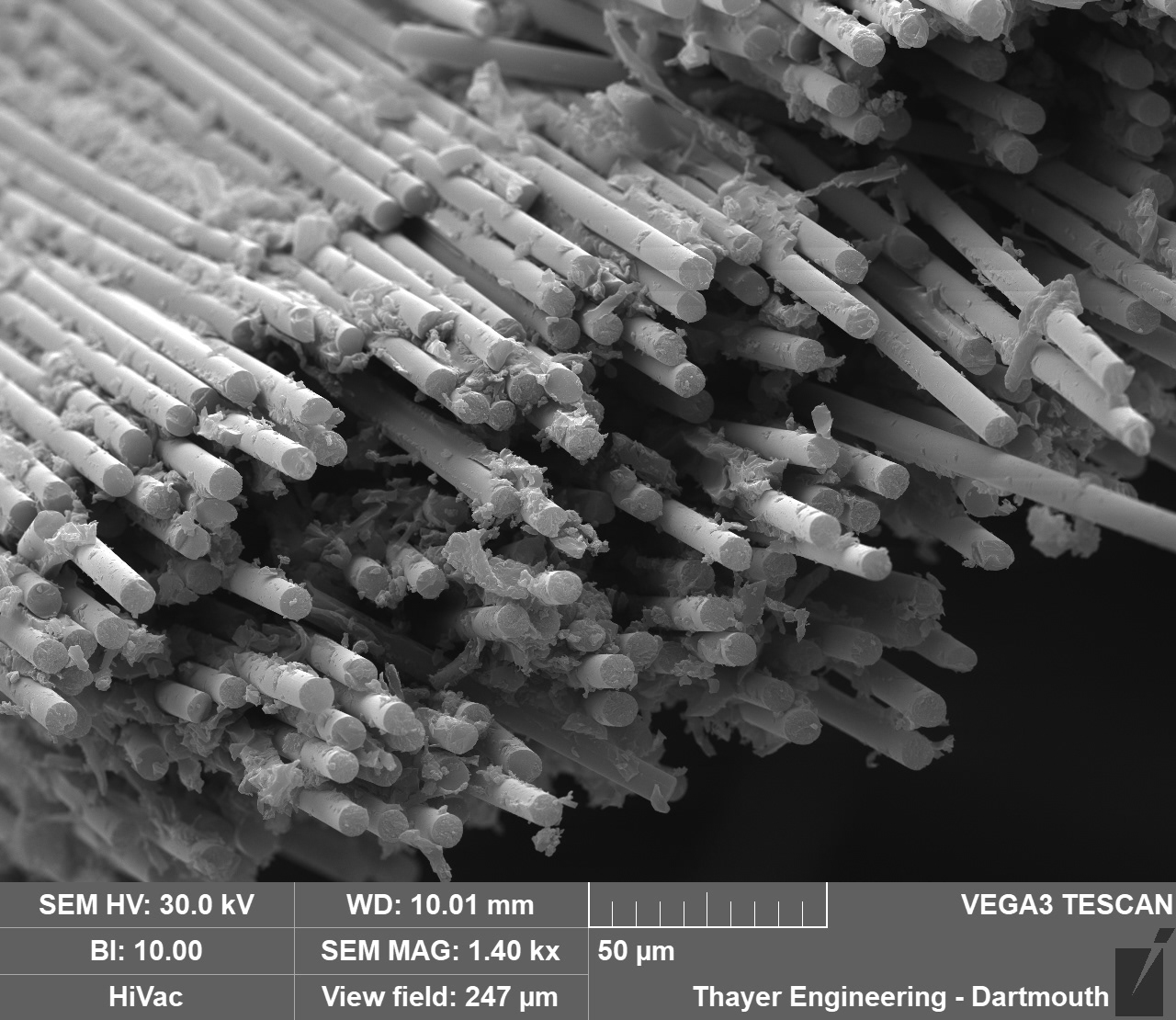

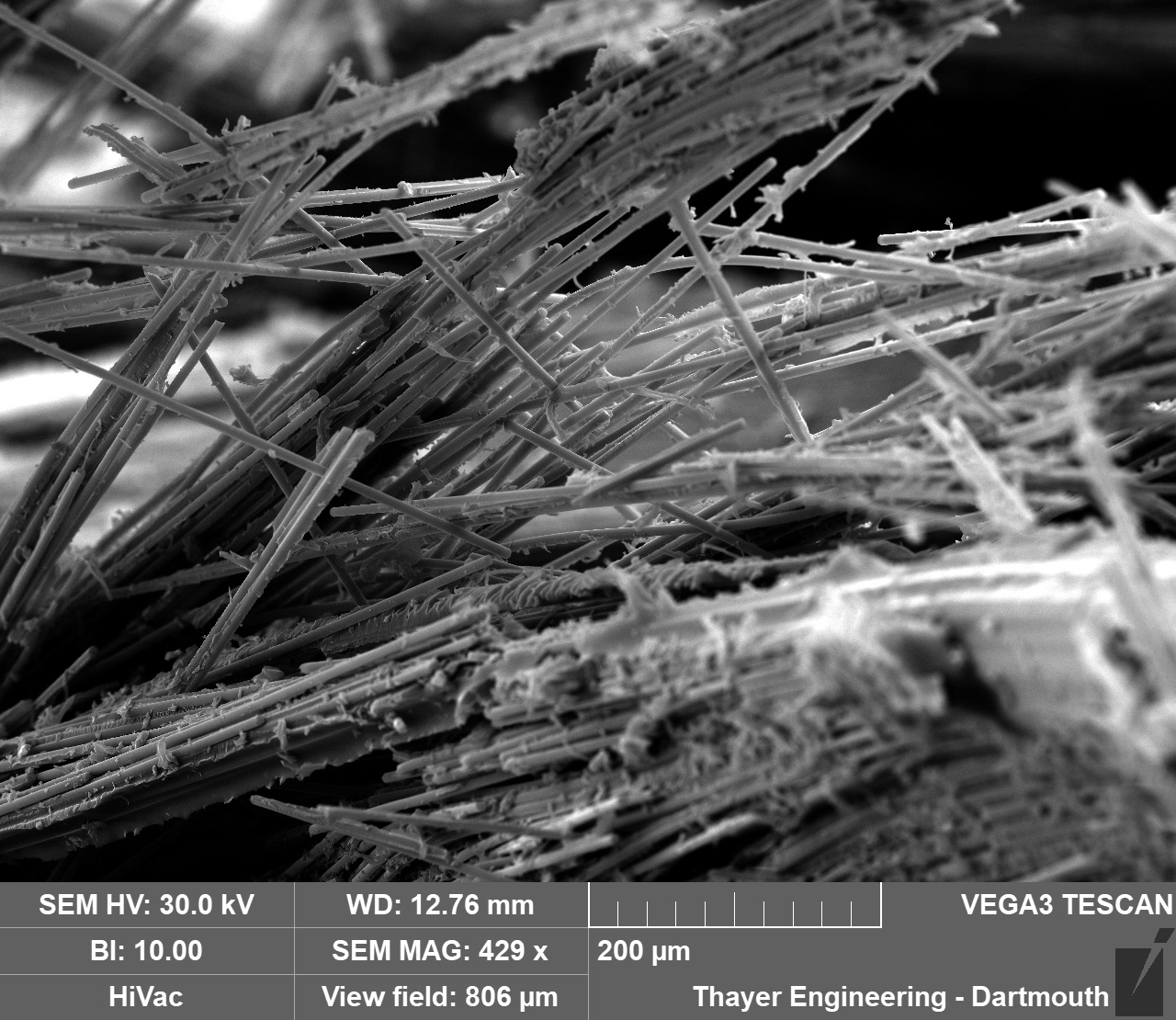

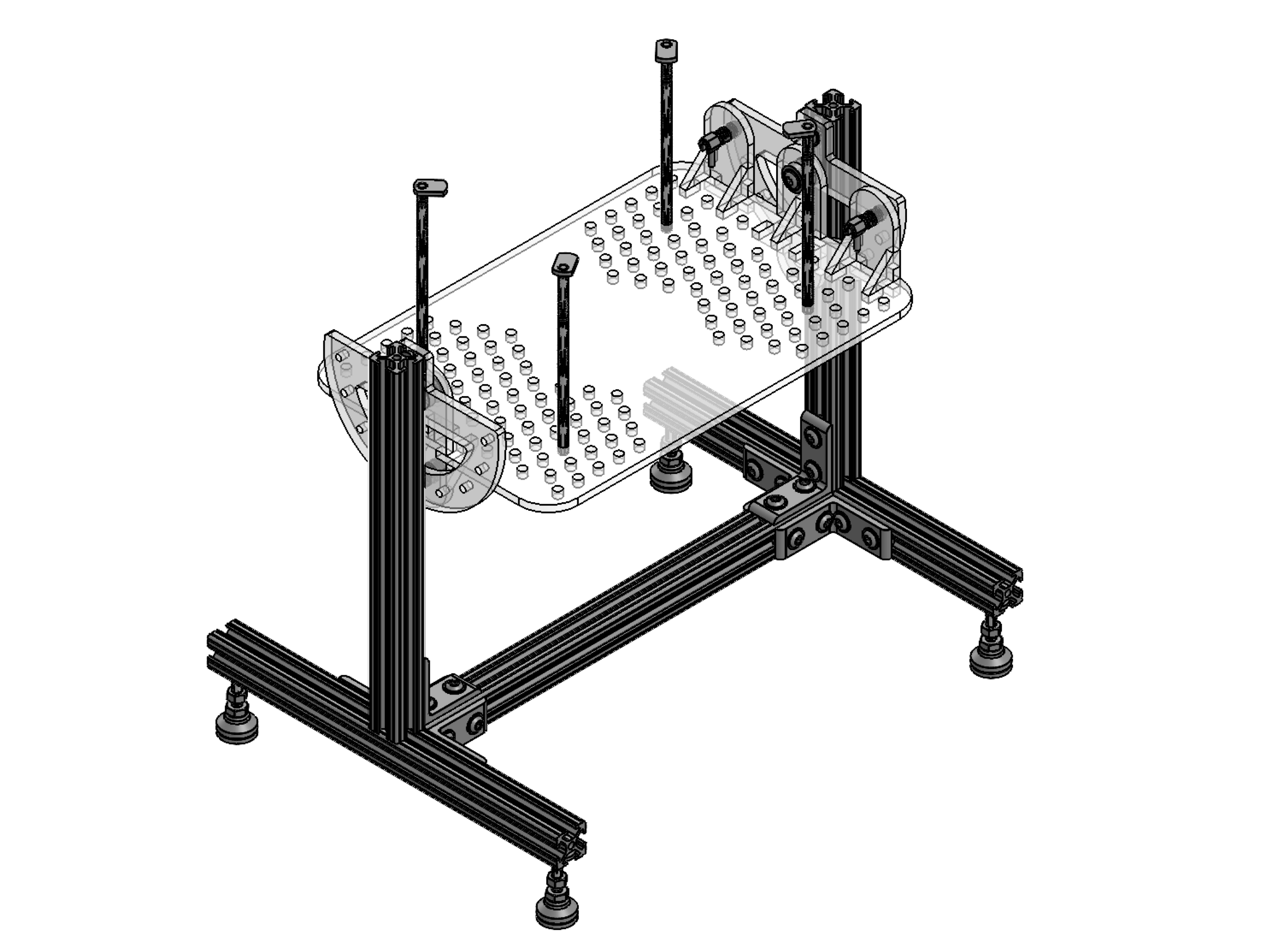

SEM imaging was used to analyze the quality of the matrix, looking for imperfections that may indicate failure in the production process of the composite. This allowed us to modify our layup procedure to balance our matrix density and compression conditions.

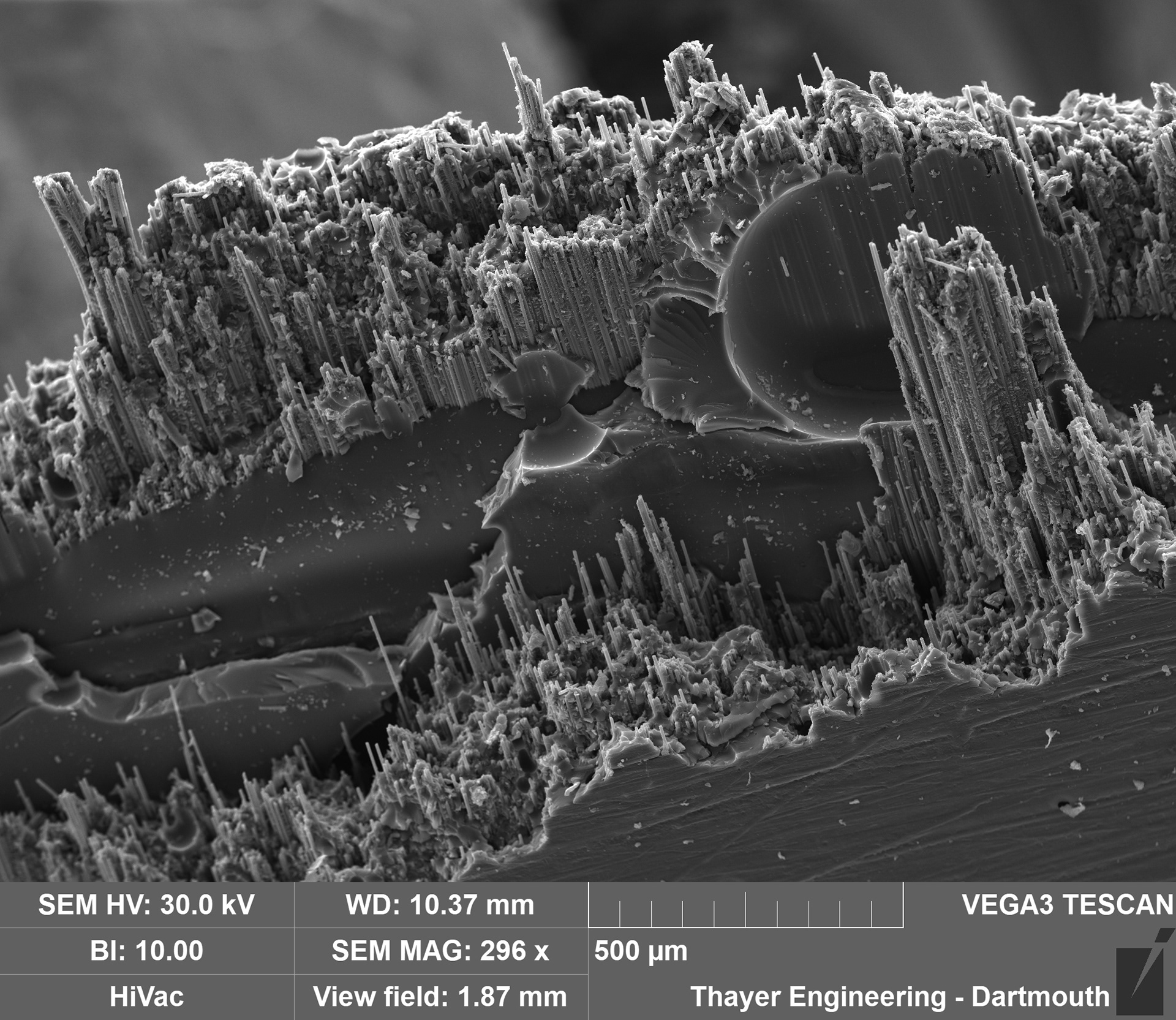

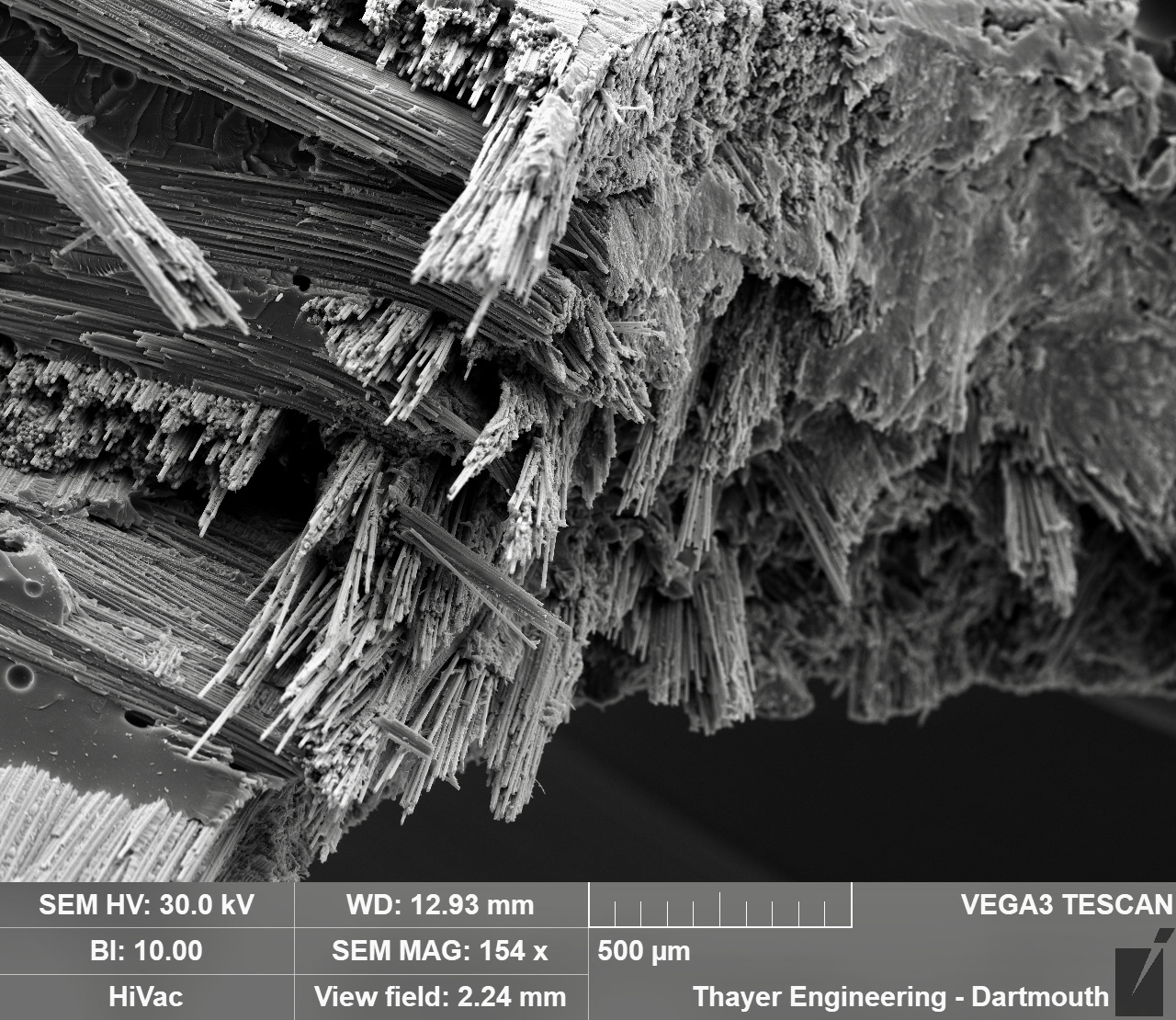

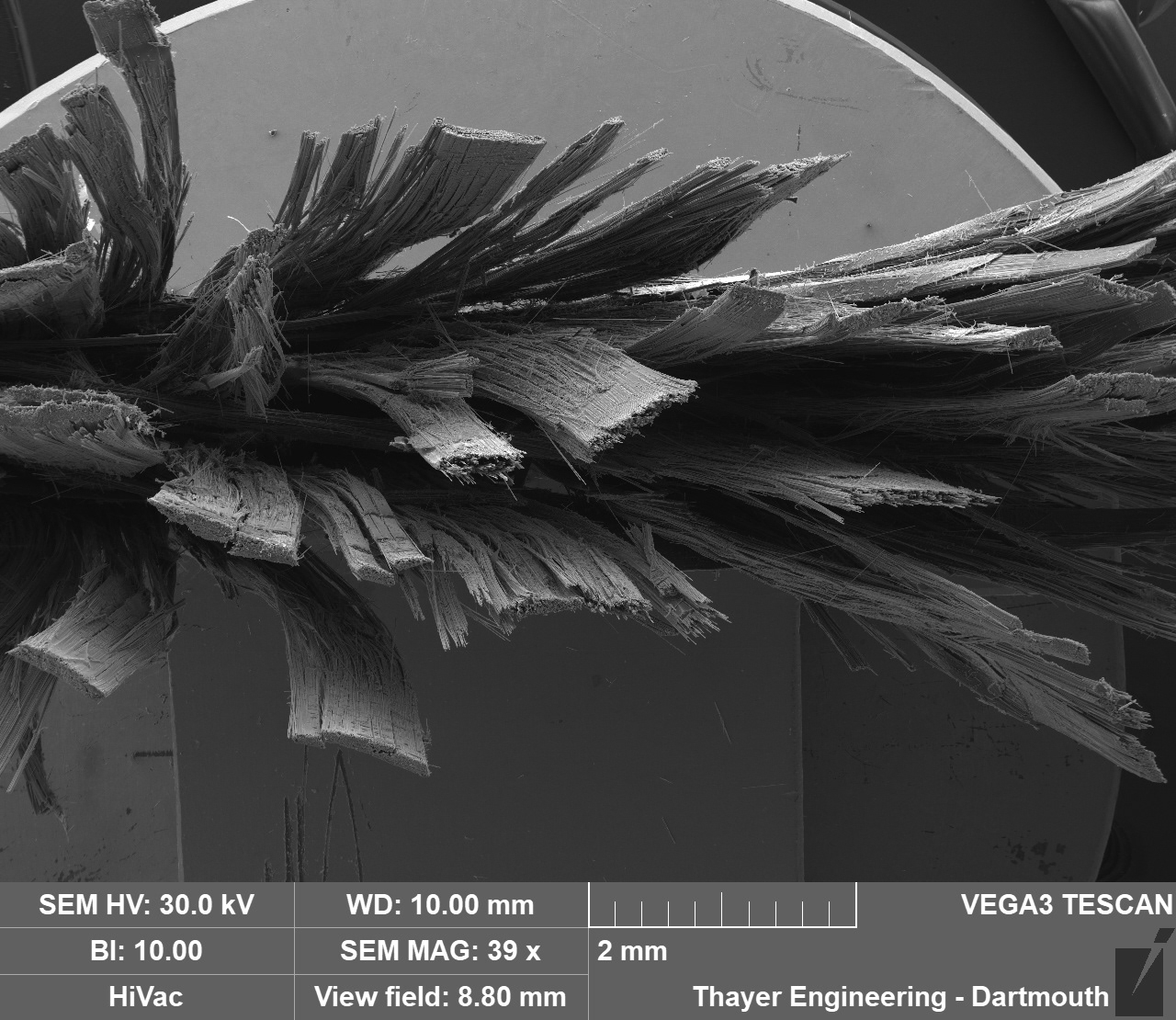

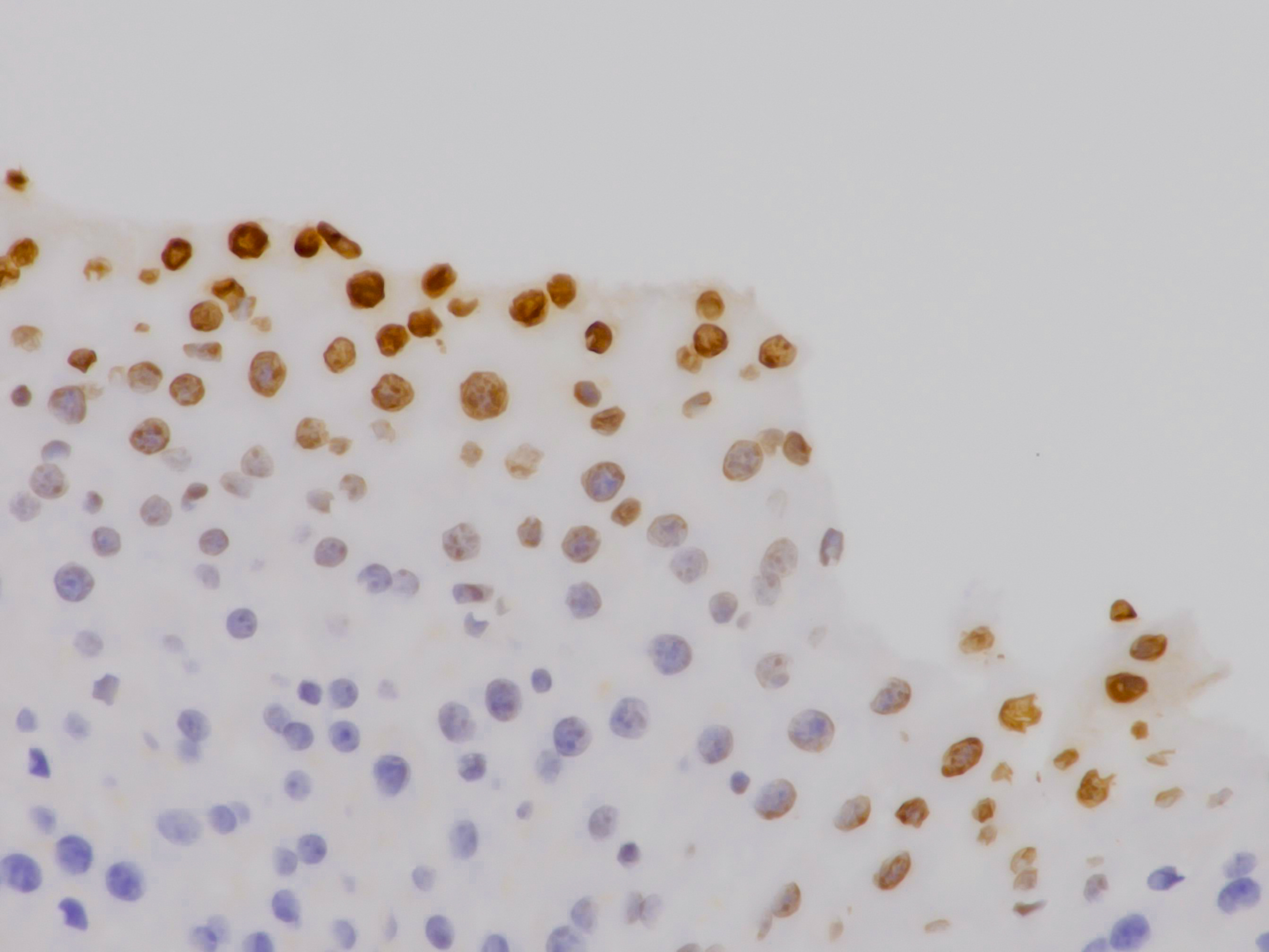

Fiber Pullout vs. Shearing

SEM imaging allowed us to look at analyze how each sample failed. If the fibers were not fully impregnated with matrix, pullout would occur vastly weakening the sample. Too much matrix increased the volume of the sample without increasing strength thus decreasing the maximum tensile stress of the sample.

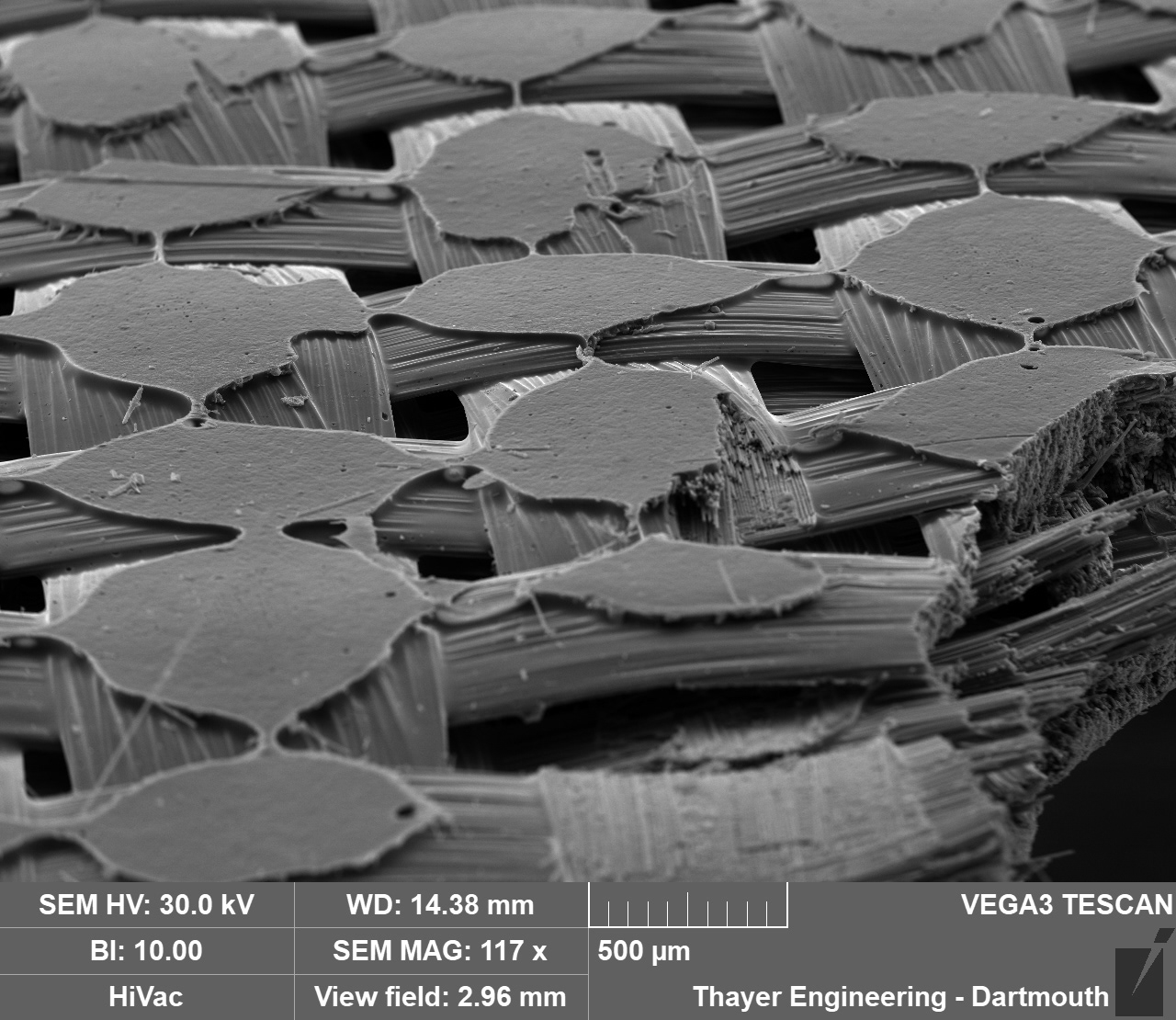

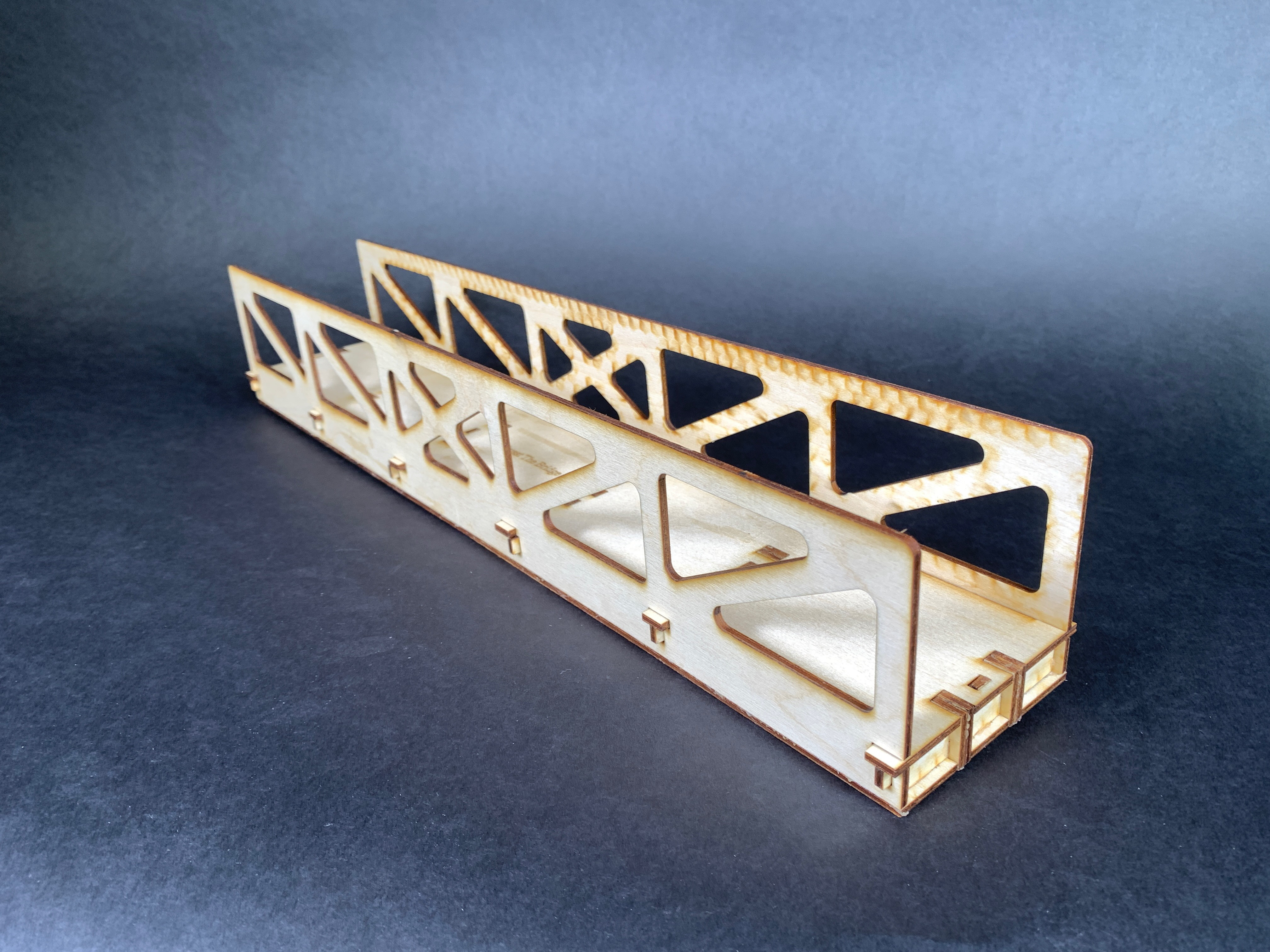

Fiber Density and Weave

Samples were also compared based on weave density and weave type allowing us to determine the relationship between these variables and the maximum sustained stress of each sample.

Final Presentation

Our conclusions and background are overviewed in this final presentation.

Final Report

The exact details of our experimental procedures, results, discussion, and conclusions are detailed throughout the final report.

Additional Images