Course Description

This course is intended to introduce students to the process of designing and manufacturing the initial prototype of a product. In doing so, it exposes students to a variety of engineering concentrations, tools, and Thayer resources to create their product.

The theme for our term was "veterans".

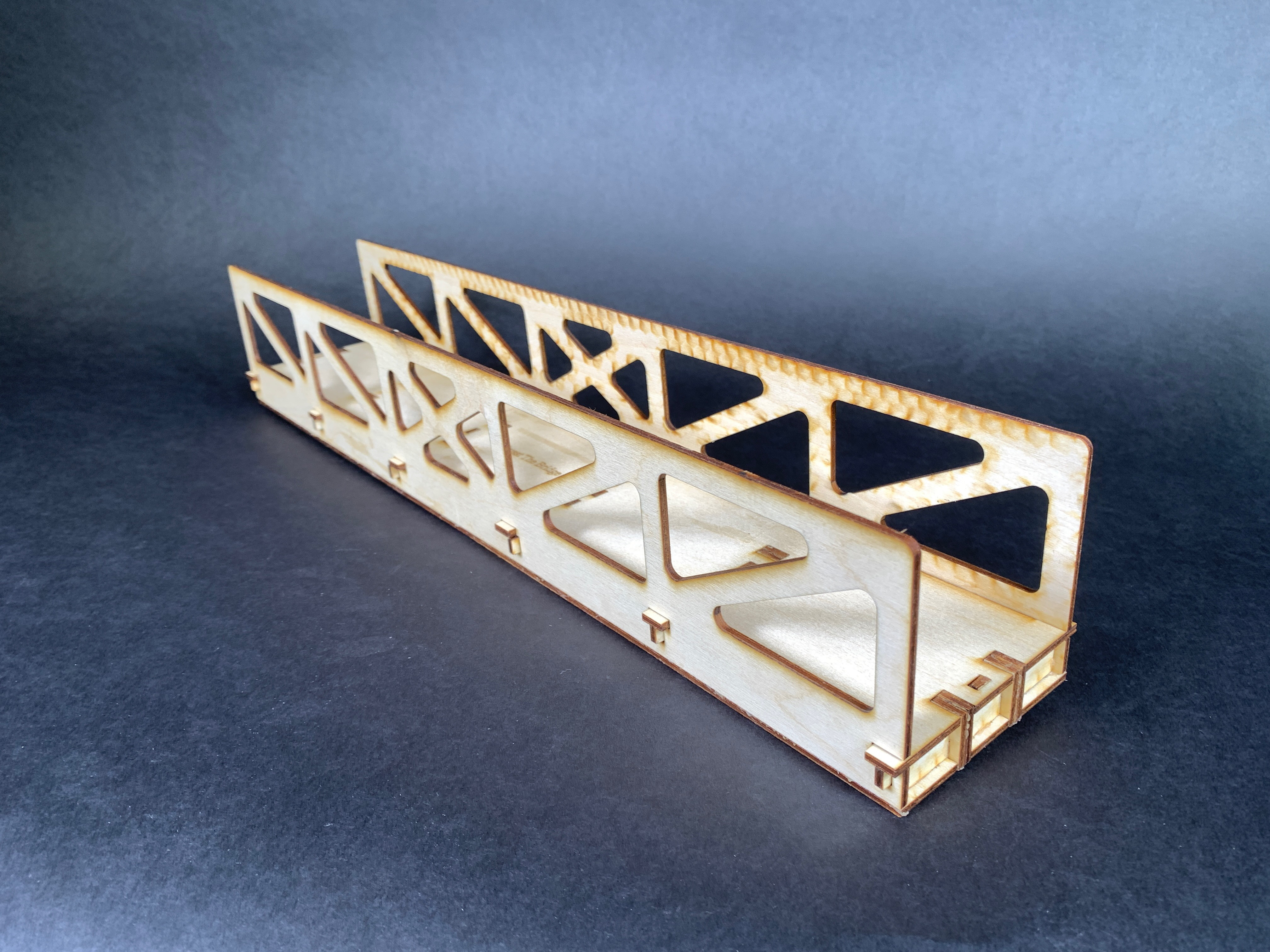

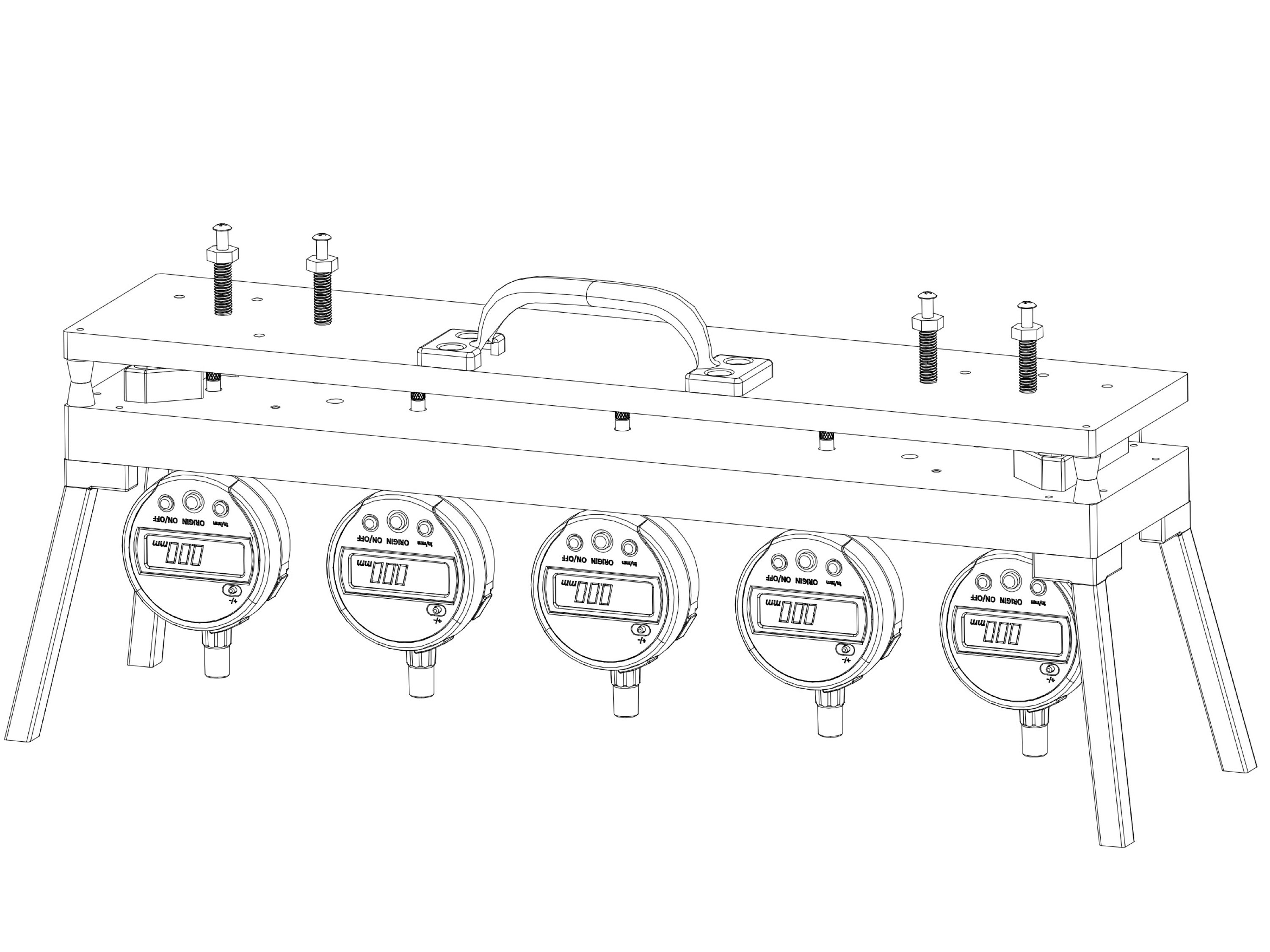

Final Prototype CAD Model

Final Prototype Model

Project Executive Summary

Access-a-Bowl is a mechanically powered kitchen appliance for single-arm amputees that helps with the small but important everyday task of securing and tilting mixing bowls. Our design is a plexiglass platform that sits on an aluminum base with threaded rods that screw into the platform to secure various sized bowls in position. Based on our research and user outreach, there are no state-of-the-art appliances intended for at-home use that can accomplish this task. All individuals we have been in contact with stated that there is no product that they know of that effectively addresses this problem. They currently either rely on someone else’s assistance or transfer the material one scoop at a time. While our intended users are single-arm amputee veterans, our device is also marketable to other single-arm amputees, a population of 41,000 individuals in the U.S., as well as individuals with limited upper body strength or mobility.

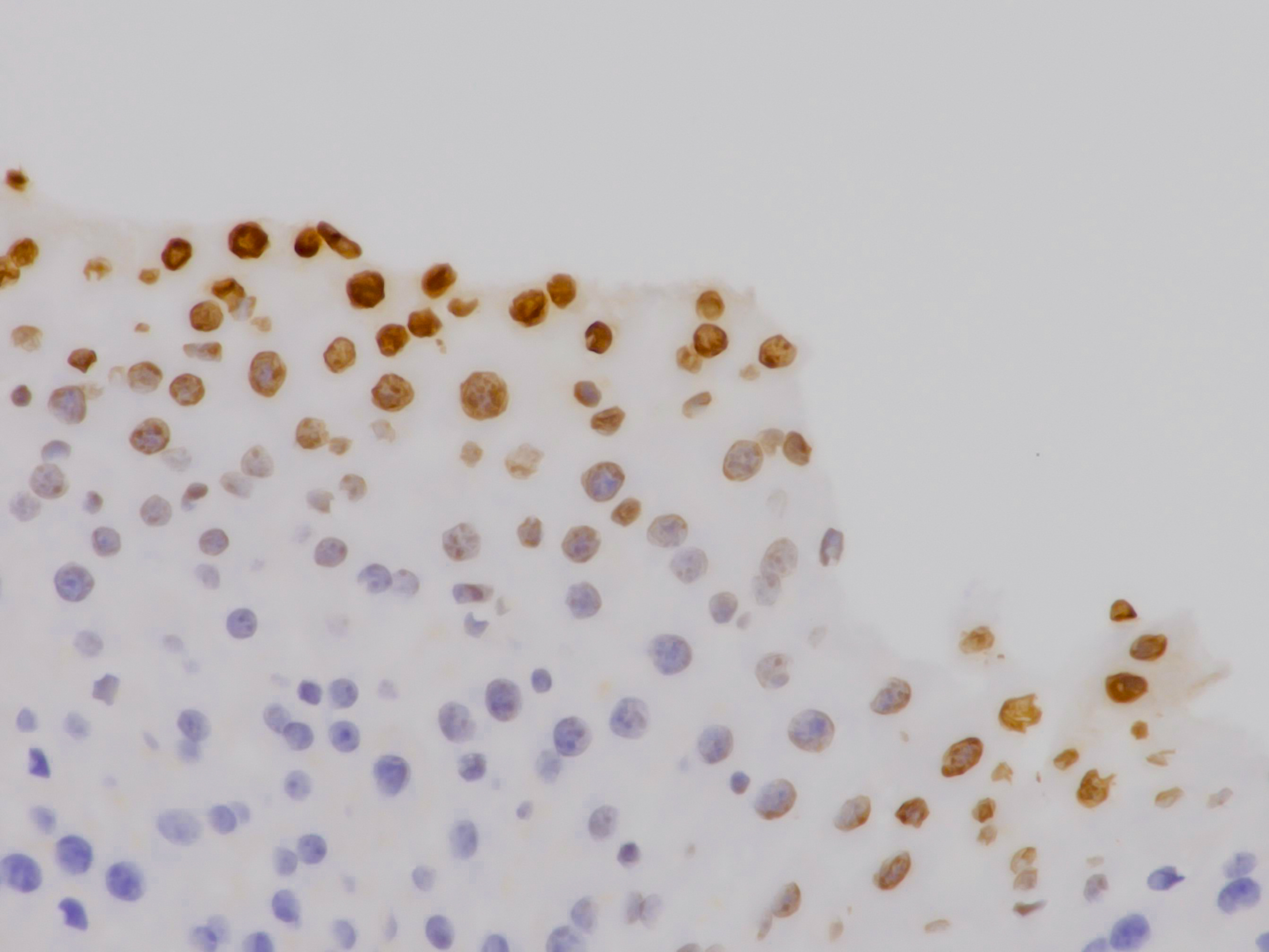

During our first round of prototyping, we designed foam core works-like prototypes and plywood models to demonstrate the basic conceptual design of our product. We used an implementation matrix to analyze how each prototype carried out the three main functions of our product – securing, lifting, and tilting a bowl – and whether our specifications were met. Based on our specification matrices and analysis of the power required, we decided to eliminate the lifting function of our device and focus on the two most important aspects of our product – securing and tilting. Once we had determined a final prototype design, we worked in the MShop to create our product using construction grade materials – primarily 80-20 aluminum framing, laser-cut acrylic, and stainless steel rods. We then assembled the product and continued to iterate through some of the finer details before subjecting it to user testing.

To test if our product met our specifications, 14 students tested our product using only one hand. We timed how long it took to secure the bowl, to remove the contents from the bowl, and then to remove the bowl from the product. We also measured the percentage of material they could transfer in 30 seconds and recorded their opinions of the device’s features. Although we tested all of our specifications, we focused on our three highest priorities: accessibility, ease of use, and stability. Our current design meets all three of these key specifications. It is accessible, with 100% of users stating that our product is “operable with one hand” in the post-test survey. It is easy to use, with participants, on average, being able to both set up and use the device in 30% less time and remove 160% more of the material from the bowl in 30 seconds using our device compared to the state-of-the-art products. Finally, our device is stable, with all users rating the stability of our product as a 9 or 10 on a 10-point scale (with 10 being the most stable).

This round of testing highlighted small improvements that the users hoped to see. None of these faults kept our users from being able to operate the product, but we want to make our user experience as pleasant as possible and thus, are brainstorming possible implementations of their feedback. Although we will not have the time to incorporate these changes into our product, we are recommending that DEFC proceed with the development of our product and want to properly document substantive additions that should be made to our final prototype.

Final Project Presentation

This final presentation overviews our process of design, following our problem identification, solution brainstorming, iteration, and product testing to our final product.

Final Project Writeup

This report was submitted to the review board and details our exact design process, highlighting our problem identification, potential solutions, the current state of the art, as well as our testing and analysis to ensure the success of our product.